Tomato Processing Plant

Categories: Processing Plant

Description of the tomato processing Plant

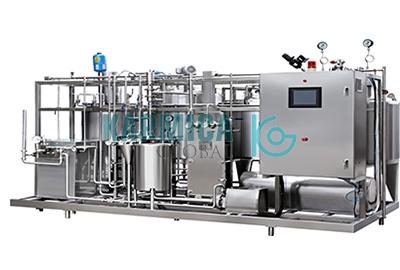

Tomatoes are usually processed for paste and the processing line mainly includes five parts: fresh tomato receiving, pre-washing and sorting section; extracting section; concentrating section; pasteurizing or sterilizing section; aseptic filling section. It is mainly composed of discharge system, hydraulic convey system, bucket elevating, washing and sorting system, crushing system, pre-heating system, pulping and refining system, evaporating& concentrating system, sterilizing system, aseptic filling system. Tomato paste in aseptic drum can be further processed to ketchup, sauces, juices in tin can/bottle/pouch, etc.

•* On-site start-up and related personnel training.

•* The finished product is of good quality and has a beautiful color.

•* High productivity, flexible production, can be customized according to customer needs.

•* Complete monitoring system with control room to monitor each processing stage.

|

Raw material handling capacity(t/d) |

60 |

150 |

250 |

500 |

750 |

1000 |

1250 |

1500 |

2000 |

|

Evaporation Form |

Double |

Double |

Three |

Three |

Three |

Three |

Three |

Three |

Three |

|

Water Consumption |

7.1 |

13.1 |

21.6 |

44.3 |

65.7 |

44.3 |

65.9 |

65.9 |

79.08 |

|

Power(kw) |

83.8 |

151.5 |

412.4 |

636.2 |

955.4 |

1291.6 |

1411.1 |

1558.1 |

1869.7 |

|

Steam Consumption(t/h) |

1.665 |

3.87 |

5.22 |

9.14 |

15.01 |

20.2 |

24.62 |

29.15 |

34.98 |

|

Compressed Air Consumption(t/h) |

66.2 |

66.2 |

66.2 |

72.2 |

72.1 |

72.2 |

72.2 |

72.2 |

86.84 |

|

Cooling Water Consumtion(t/h) |

125 |

317 |

307 |

585 |

825 |

1075 |

1410 |

1630 |

1956 |

Tomato Processing Plant Related Products

More products related to Tomato Processing Plant